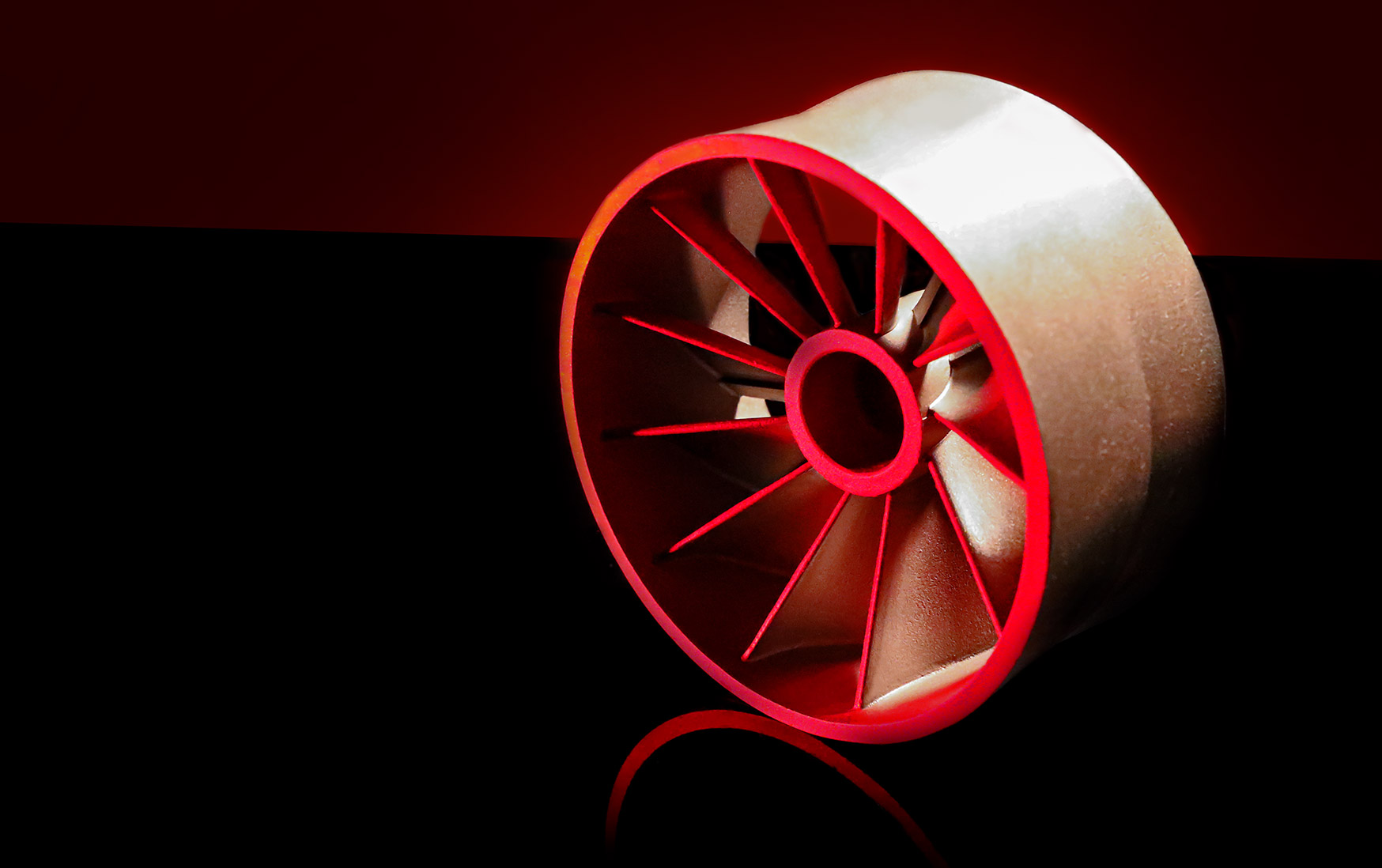

SWIRLER

FOCUS:

PROCESS

FORMULATION

THE PROBLEM

The swirler is a nickel alloy casting with thin walls, many think to thin sections that are difficult to feed, a complex internal geometry that is difficult to inject and shell, and tight limits on dimensions and NDT requirements.

THE SOLUTION

Casting simulations and use of rapid prototype patterns were used to come up with a gating system and pouring parameters that would allow for sufficient solidification.

Results were verified with internal NDT, an additional challenge due to the tight limits from the NDT specifications. Special tooling utilising soluble cores was leveraged to allow for the complex geometry to be injected. Trials to optimize mould manufacture on our fully automated lines to ensure good coverage during mould build to reduce scrap and rework to acceptable levels. We were able to leverage decades of process experience and specially developed and proprietary systems.

THE IMPACT

Texmo’s expertise in both the new product development and process development teams meant that castings were productionised to meet the customers tight specifications despite the technical challenges presented. This allowed Texmo to deliver a technically challenging part at an economical price for use in the demanding application of industrial gas turbine engines.

CURRENT TOOLING

COSTS TOO HIGH?

To find out how Texmo Precision Castings can help you, arrange a chat with Andy Price.